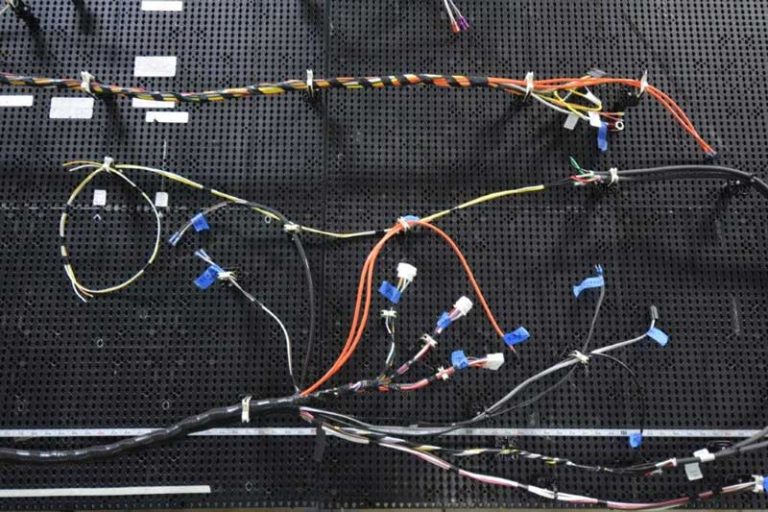

Wire harnesses are groups of wires and/or cables engineered into an assembly for efficiency and manufacturability. Wire harnesses also include crimped terminals or ferrules, welded splices, soldered connections, and specialty components that allow for connection points across the length and layout of the harness allowing connection to other electrical components.

A wire harness supports the core functions of a product by carrying its power, data, and signals.

Harnesses Optimized for Work

Wire harnesses also include terminals that allow for connection points across the length and layout of the harness allowing connection to other electrical components. Wire harnesses essentially provide an optimized way to keep electrical systems organized and ensure that

- power

- data

- signals

flow as designed. Bundling together wires and cables allows engineers and electrical contractors to design devices which are more

- streamlined

- cost effective

- easily manufactured

- easily documented

Wire harnesses range from a relatively simple set of wires, terminations, and connectors to the very complex with many wire types and hundreds connection points. While the individual wires or cables in a wire harness are usually covered in a basic layer of sheathing; they are not as ruggedized as heavier-duty cable assemblies.

Wire Harness Manufacturing

DECA Manufacturing builds wire harnesses with materials up to 28 gauge. We create custom layouts for each harness we manufacture to ensure quality, repeatability, and efficiency. The services we offer include:

- engineering support

- experienced harness board building

- wire marking and labeling

- automated cut/strip capabilities

- terminal press crimping

- hand assembly with advanced cable tie tools

We have a wide variety of equipment, applicators, and hand tools available in our facility to ensure quality, reliability, and efficiency. We regularly obtain the specialized connectors and military spec components which are required for specialized harnesses and handle custom layouts.

DECA has access to the materials, tools and expertise to build the customized wire harnesses your application requires. To fabricate your wire harnesses we need the following information:

- prints, drawings or schematics

- bill of materials (BOM)

- approved vendor list (AVL)

Testing and Quality control

All our products are 100% inspected and many are 100% tested leveraging Cirris brand test systems to make sure the products function to the required level.

More information about our commitment to quality is available.

DECA Is Now Certified for CMMC Level 1

DECA Manufacturing is pleased to announce that we are now certified for a CMMC Level 1. CMMC is Cyber Security Maturity Model Certification and is designed to help protect federal contract information, e.g. information which is: not intended for public