DECA Manufacturing serves a wide variety of clients both military and civilian. We build products for

- Top Tier defense contractors

- Tier 1 automotive suppliers

- industrial segments as noted below.

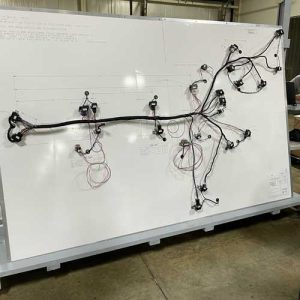

We have built cables for weapons systems, recreational vehicles, and industrial pumps. We have even used our experience building powered cables to manufacture high-strength, breakaway lanyards. No matter what your next project is, we have the equipment, experience and capacity to build the “nervous system” for your final product.

There key areas we focus on include:

- military & defense (Mil/Aero, Milspec)

- performance automotive & specialty vehicle

- construction equipment

- commercial food processing

- control systems

- warehouse automation

- marine and RV

Military & Defense

DECA has been trained to work with both PTAC and PTAP; and we have been working with government contractors as a secondary supplier for years. We understand the requirements that government contractors must fulfill include a wide range of regulations and business practices encompassing business elements such as

- hiring requirements

- safety guidelines

- SAM.gov system navigation

- cybersecurity

- and more

Defense (MilAero & MilSpec) Experience

Many of our government-related projects have been defense related. These projects often require ruggedization, failure-proof reliability, and specialized services such as IPC/WHMA-A-620 certified soldering. Some of DECA’s recent projects have included:

- cabling for laser guided munitions

- wire harnesses for drones

- overmolded cables for military vehicles

DECA Manufacturing also understand the high level of precision, reliability, and ruggedization needs DOD projects require.

Capabilities Statement

DECA Manufacturing does have a capabilities statement available.

Aftermarket/Performance Automotive & Specialty Vehicle

We often build wire harnesses and cable assemblies for specialty automotive and transportation projects. These components either improve the performance of vehicles or just keep them running. For example we have built harnesses which

We often build wire harnesses and cable assemblies for specialty automotive and transportation projects. These components either improve the performance of vehicles or just keep them running. For example we have built harnesses which

- update and improve cars such as corvettes

- keep older commercial vehicles running.

These wire harnesses, also known as “octopus” cables monitor and control key automotive functions such as

These wire harnesses, also known as “octopus” cables monitor and control key automotive functions such as

- monitor tire pressure, engine temperature, oil pressure

- control lights, brakes and wipers, horn, etc.

- control doors and windows

- connect instrument cluster with components they monitor

Whether you are seeking to improve your car’s performance, restore a vehicle, or update the functionalities of an existing vehicle, contact us today to get started.

Industrial

We also work with industrial customers who are looking for components to transfer power and data within their final products. With today’s level of automation and IOT, the success of your products depends on the quality of their “central nervous system, which we can provide in the form of

We also work with industrial customers who are looking for components to transfer power and data within their final products. With today’s level of automation and IOT, the success of your products depends on the quality of their “central nervous system, which we can provide in the form of

- cable assemblies

- wire harnesses

- wire leads

These components are highly customizable in terms of types of wires, connectors, and protective coverings. We can also include small components such as sensors or thermostats to provide your cable assembly or wire harness with more functionality. If you are looking for a more complete solution, we also build complete electro-mechanical assemblies, aka box builds. Examples of industrial segments we serve include:

These components are highly customizable in terms of types of wires, connectors, and protective coverings. We can also include small components such as sensors or thermostats to provide your cable assembly or wire harness with more functionality. If you are looking for a more complete solution, we also build complete electro-mechanical assemblies, aka box builds. Examples of industrial segments we serve include:

- construction equipment

- commercial food processing

- control systems

- warehouse automation

To start your next project request a quote today.

Get Started today!

- Download our capabilities statement

- Explore our products and services

- Learn about our Design and Prototype options

DECA Is Now Certified for CMMC Level 1

DECA Manufacturing is pleased to announce that we are now certified for a CMMC Level 1. CMMC is Cyber Security Maturity Model Certification and is designed to help protect federal contract information, e.g. information which is: not intended for public