Reasons for Laser Wire Stripping

Some projects require more precise wire stripping because

- nicking the wires can cannot be tolerated by the design requirements and specification

- tiny gauge wires cannot be reliably stripped with metal blades.

- complex strip patterns

- wire coverings are difficult to remove with hand or mechanical stripping methods.

In these instances, laser wire stripping is a great option.

Laser Stripping Capabilities

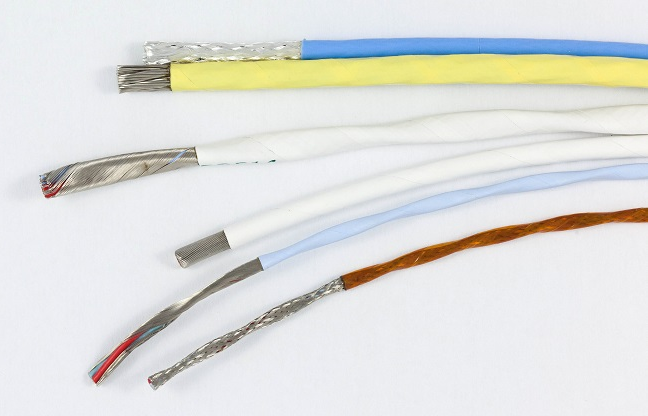

Laser stripping works by vaporizing the wire’s outer jacket resulting in a nick-free cut every time. Our laser strip capabilities offers

- nick-free stripping of small diameter fine wire

- cut diamonds or other shapes into ribbon cable

- high-spec nick-free requirements for other gauges of wire and specialty jacketing.

For example

- PTFE

- ERFE

- XLETE

are all examples of insulation which are well-suited to laser wire stripping. Some of the industries, whose products require more precise wire stripping include:

- military and defense

- aerospace

- medical/healthcare

- automotive

- consumer electronics

- data and telecom

At DECA our technicians and equipment can easily provide nick-free stripping of wire and cable jackets including ribbon cables and multi-conductors at small gauges. Our laser stripping capabilities will handle most materials (such as PVC) except ferrous and non-ferrous metals.

DECA’s laser stripping services optimize wire cut/strip for high-performance and eliminates the risk of creating nicks which would result in poor connections or handle wire that is too small to effectively blade cut. Cut and stripped wires can then be incorporated into wire leads, wire harnesses, or even cable assemblies which fit your product requirements.

DECA’s Capabilities

DECA has access to the materials, tools and expertise to build the customized prototypes and products your application requires. We can also acquire the specialized connectors or military spec components required for your projects. Using DECA to fabricate components that match your specifications allow you to focus your manufacturing processes and expertise on other tasks. Simplifying and improving your product designs can also lower overall your production costs.

Testing and quality control

All our products, including wire leads, are tested using the Cirris System to make sure the products function to the required level.

Learn more about our commitment to quality and certifications.

Bringing Wearable Tech to Life

At DECA we love to think of our products in broader terms than simply wire harnesses or cable assemblies. We tend to think of them as a your final product’s central nervous system. While we build harnesses for many different

Green shoots at DECA, growing manufacturing and our future

Learn more about DECA Manufacturing and how it is growing our future. Learn about our: vision team capabilities industries served Talk to us about your next project. call 419-884-0071 online quote All our products are 100% inspected and many are